news

How does modular design improve the maintenance efficiency and production performance of the Extruder single barrel system?

What is a Single Screw Barrel?

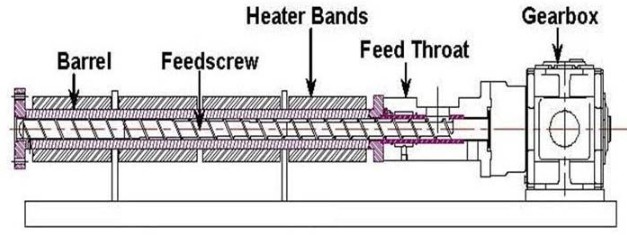

1. Definition and Function

The main function of a Single Screw Barrel is to push the plastic material from the feed port into the barrel through the rotation of the screw, and extrude it from the barrel outlet after heating and plasticization. Ensure that the material is evenly heated and fully plasticized, and provide high-quality raw materials for subsequent processing steps.

2. Structural Features

The structural design of the Single Screw Barrel is very precise, and the inner wall of the barrel is processed by advanced CNC machining centers and precision measurement technology to ensure that it is smooth and flawless. This design can effectively reduce the friction of the material during the extrusion process, reduce energy consumption, and improve production efficiency.

What are the main materials of a Single Screw Barrel?

1. Material selection

Single Screw Barrel is usually made of highly wear-resistant and corrosion-resistant alloy steel or stainless steel. It has excellent mechanical properties and chemical stability, can withstand high temperature, high pressure and high friction working environment, and ensure that the barrel maintains good performance during long-term operation.

2. Heat treatment process

Single Screw Barrel Suppliers In order to improve the hardness and service life of the barrel, the Single Screw Barrel will undergo a special heat treatment process during the manufacturing process. It can change the microstructure of the material, improve its strength and toughness, make it more wear-resistant and corrosion-resistant, and adapt to the processing needs of various plastic materials.

What are the advantages of Single Screw Barrel?

1. High efficiency and energy saving

The design of Single Screw Barrel is characterized by high efficiency and energy saving. Its unique screw and barrel matching design can ensure that the material is evenly heated and fully plasticized during the extrusion process, reducing energy consumption. This design saves energy and improves production efficiency, bringing economic benefits to the enterprise.

2. Low noise and vibration

The noise and vibration generated by Single Screw Barrel during operation are very low. This is mainly due to its precise manufacturing process and reasonable structural design, which can effectively reduce mechanical friction and vibration. Low noise and vibration improve the comfort of the operating environment and help protect the health of operators.

3. Long life

Single Screw Barrel is made of highly wear-resistant and corrosion-resistant materials and special heat treatment process, and has a very long service life. Even in high temperature, high pressure and high friction working environment, the barrel can maintain good performance, reduce the frequency of maintenance and replacement, and reduce the maintenance cost of the enterprise.

4. Summary

Single Screw Barrel is the core component of the extruder, with the advantages of high efficiency and energy saving, low noise and vibration, and long life. Made of highly wear-resistant and corrosion-resistant alloy steel or stainless steel, Single Screw Barrel Suppliers makes it undergo a special heat treatment process to adapt to the processing needs of various plastic materials. The wide application of Single Screw Barrel brings economic and environmental benefits to enterprises, and it is an indispensable and important equipment in modern industrial production.

| Design Features | Detailed description |

| Smooth Inner Wall | The use of advanced CNC machining centers and precision measurement technology ensures that the inner wall of the barrel is smooth and flawless, reducing material friction. |

| High Wear Resistance | The use of highly wear-resistant materials and special heat treatment processes improves the hardness and service life of the barrel. |

| Matching Design | The matching design of the screw and barrel ensures that the material is evenly heated and fully plasticized during the extrusion process, reducing energy consumption and noise. |

| Modular Design | The modular design of the extruder single barrel is conducive to rapid replacement and maintenance, improving production efficiency. |

Design features and advantages of Single Screw Barrel

As the core component of the extruder, Single Screw Barrel plays a vital role in industries such as plastic processing and food processing. Its design features ensure that the material is evenly heated and fully plasticized during the extrusion process, and also reduce energy consumption, reduce noise and vibration, and improve the comfort of the operating environment.

1. Smooth inner wall

Advanced processing technology

Single Screw Barrel adopts advanced CNC machining center and precision measurement technology to ensure that the inner wall of the barrel is smooth and flawless. CNC machining center can achieve high-precision processing to ensure that the surface roughness of the inner wall of the barrel reaches an extremely low level. Precision measurement technology is used to detect and control the size and shape errors during the processing process to ensure the geometric accuracy of the inner wall of the barrel.

Reduce friction and energy consumption

The smooth inner wall can effectively reduce the friction of the material during the extrusion process. The reduction of friction reduces energy consumption and reduces the residence time of the material in the barrel, improving production efficiency. The smooth inner wall can also reduce the residue of the material in the barrel, avoid the degradation and deterioration of the material, and ensure the quality of the product.

2. High wear resistance

High-quality materials and heat treatment process

Single Screw Barrel is made of high wear-resistant materials and special heat treatment process to improve the hardness and service life of the barrel. High wear-resistant materials have excellent mechanical properties and chemical stability, and can withstand high temperature, high pressure and high friction working environment. Special heat treatment process improves the strength and toughness of the material by changing its microstructure.

Extend service life

High wear resistance and special heat treatment process enable Single Screw Barrel to maintain good performance during long-term operation. Even in high temperature, high pressure and high friction working environment, the barrel can maintain good performance, reduce the frequency of repair and replacement, and reduce the maintenance cost of the enterprise. Improve production efficiency, extend the service life of the barrel, and bring economic benefits to the enterprise.

3. Matching design

Matching of screw and barrel

The screw and barrel of Single Screw Barrel adopt matching design to ensure that the material is evenly heated and fully plasticized during the extrusion process. The matching design of screw and barrel includes matching of screw pitch, thread depth, thread shape and other parameters with barrel size, shape, material and other parameters. It can ensure that the material is evenly heated and fully plasticized during the extrusion process, and improve the processing quality of the material.

Reduce energy consumption and noise

The matching design reduces energy consumption, noise and vibration. The matching design of the screw and barrel can reduce the friction and impact of the material during the extrusion process and reduce energy consumption. The matching design can also reduce mechanical friction and vibration, reduce noise and vibration, and improve the comfort of the operating environment.

4. Modular design

Quick replacement and maintenance

Single Screw Barrel adopts modular design, which is conducive to quick replacement and maintenance. The modular design divides the barrel into multiple independent modules, each of which can be replaced and maintained independently. It can reduce downtime and improve production efficiency.

Improve production efficiency

Modular design can improve production efficiency, reduce downtime, and bring economic benefits to the enterprise. Modular design can also improve the flexibility and adaptability of the barrel to meet different production needs.

| Design features | Description | Advantages |

| Smooth inner wall | Using advanced CNC machining centers and precision measurement technology. | Reduce friction and energy consumption; reduce material residue, avoid degradation and deterioration, and ensure product quality. |

| High wear resistance | Made of highly wear-resistant materials and special heat treatment processes. | Extend service life, reduce maintenance and replacement frequency, and reduce maintenance costs; improve production efficiency and bring economic benefits to the enterprise. |

| Matching design | The screw and barrel are designed to match. | Reduce energy consumption, noise and vibration; improve material processing quality; improve the comfort of the operating environment. |

| Modular design | The barrel is divided into multiple independent modules, each of which can be replaced and maintained independently. | Quick replacement and maintenance, reduce downtime, and improve production efficiency; improve the flexibility and adaptability of the barrel to meet different production needs. |

Working principle of Single Screw Barrel

1. Feeding stage: The material enters the barrel of the extruder through the Single Screw Barrel, usually in the form of granules or powder.

2. Conveying stage: When the screw rotates, its threads push the material forward, exert shear force and friction force on the material, and gradually compact the material.

3. Melting and plasticizing stage: As the material is pushed forward, the heating device in the barrel heats the material and gradually melts it. The shearing action and friction heat generated by the screw promote the melting and plasticizing of the material.

4. Homogenization and mixing stage: Under the rotation of the screw, the molten material is fully mixed and homogenized to form a uniform melt.

5. Extrusion stage: The homogenized melt is extruded from the die head by the thrust of the screw and passes through the mold to form the desired shape and size.

Applicable materials for Single Screw Barrel

1. Plastic materials: thermoplastics such as PE, PP, PVC, PS, etc.

2. Rubber materials: natural rubber, synthetic rubber, etc.

3. Composite materials: composite materials such as plastic and fiber, plastic and filler.

4. Food materials: raw materials in food processing such as starch and sugar.

5. Other materials: insulation materials for wires and cables, building materials, etc.

Single Screw Barrel has a modular design and intelligent control system, which can flexibly adapt to the processing needs of different materials. Therefore, it is widely used in many industries such as plastics, rubber, food, wires and cables. By selecting the appropriate screw and barrel configuration, the processing requirements of different materials can be met, and production efficiency and product quality can be improved.

The essence of modular design

The complex Single Screw Barrel?system is decomposed into several independent functional modules, each of which has clear functions and interfaces and can be independently designed, manufactured, tested and maintained. These modules are connected and communicated through standardized interfaces to form a complete system. The traditional monolithic structure is transformed into a system composed of multiple independent modules. These modules may include power modules, heating modules, cooling modules, control modules, extrusion modules, etc. Each module has a specific function and can be flexibly combined with other modules to meet different production needs.

The core of modular design lies in "interchangeability" and "scalability". Interchangeability means that different modules can be replaced with each other without affecting the overall function of the system; scalability means that the system can expand or reduce its functions by adding or removing modules to meet the ever-changing production needs.

Advantages of modular design of Single Screw Barrel system

1. Simplify maintenance procedures

The traditional Single Screw Barrel?system usually adopts an integral structure, and the components are tightly connected, making it difficult to maintain them separately. Once a component fails, it is often necessary to disassemble the entire machine, which is time-consuming and labor-intensive, and it is easy to damage other components during maintenance. Each module of the modular design is independent. When a module fails, it can be quickly isolated and replaced or repaired without affecting the normal operation of other modules.

Modular design makes the maintenance process more standardized and normalized. Each module is equipped with a detailed maintenance manual, and maintenance personnel can follow the steps in the manual without deep professional knowledge. The uniformity of modular interfaces also reduces the dependence on professional skills, allowing ordinary technicians to complete most maintenance tasks after simple training.

2. Reduce downtime and improve productivity

Downtime is a key factor in industrial operations, which affects productivity and profitability. The traditional Single Screw Barrel?system requires a long downtime due to complex maintenance, while the modular design reduces downtime by quickly replacing modules. When a module fails, it can be quickly replaced with a spare module to quickly restore the system to full load operation.

Modular design also improves the reliability and stability of the system. The failure of a single module will not affect the operation of the entire system. Reduce the possibility of catastrophic failures and ensure the continuous and stable operation of the production line.

3. Reduce maintenance costs

Maintenance costs are an important part of the operating costs of the Single Screw Barrel system. Traditional Single Screw Barrel systems often require high maintenance costs, including special tools, expertise and labor costs, due to their complex maintenance. Modular design reduces maintenance costs by simplifying the maintenance process and reducing the need for professional skills and tools. It also allows the use of standardized components, which are easier to purchase and less expensive, reducing maintenance costs.

Modular design also indirectly reduces operating costs by reducing downtime and improving productivity. The system can quickly return to full load operation, reducing production losses and waste, and improving the economic benefits of the enterprise.

4. Enhance system flexibility and scalability

The traditional Single Screw Barrel?system is difficult to adjust flexibly due to its fixed structure. Modular design enables the system to easily adapt to different production needs by adding or replacing modules. When an enterprise needs to produce different types of materials, it can be achieved by replacing the extrusion module; when an enterprise needs to expand its production scale, it can be achieved by adding power modules and heating modules.

5. Improve system reliability and performance, ensure product quality

The traditional Single Screw Barrel?system often has a certain risk of failure due to its complex structure, which may affect the quality and production efficiency of the product. Modular design improves the reliability and performance of the system through redundant design and the use of high-quality components. Modular design allows optimization for specific functions, the use of high-quality components and materials, and improves the overall performance of the system.

Practical application of modular design

1. Plastic processing industry

In the plastic processing industry, the Single Screw Barrel system is widely used in the production of plastic pipes, profiles, films and other products. Modular design enables the Single Screw Barrel system to easily adapt to different types of plastic materials and production processes.

2. Rubber molding industry

In the rubber molding industry, the Single Screw Barrel system is used in the production of rubber sealing strips, rubber tubes and other products. Modular design enables the Single Screw Barrel system to cope with the high viscosity and high elasticity of rubber materials. By optimizing the design of the extrusion module and the cooling module, the uniform extrusion and rapid cooling of the rubber material can be ensured, and the quality and production efficiency of the product can be improved.

3. Composite material manufacturing industry

In the composite material manufacturing industry, the Single Screw Barrel system is used for the production of fiber-reinforced composite materials, particle-reinforced composite materials and other products. The modular design enables the Single Screw Barrel system to flexibly cope with different types of reinforcement materials and matrix materials. By adding special mixing modules and extrusion modules, the uniform mixing and extrusion of reinforcement materials and matrix materials can be achieved to produce high-performance composite materials.

Future development trend of modular design

1. Intelligent integration

With the continuous development of technologies such as the Internet of Things, big data, and artificial intelligence, modular design will be deeply integrated with these advanced technologies to achieve intelligent integration of the Single Screw Barrel system. By integrating intelligent devices such as sensors, controllers, and actuators, real-time monitoring, intelligent diagnosis, and automatic adjustment of the Single Screw Barrel system can be achieved to improve the reliability and performance of the system.

2. Green environmental protection

Today, with the increasing awareness of environmental protection, green environmental protection has become an important development direction in the field of industrial manufacturing. Modular design will pay more attention to the use of environmentally friendly materials and energy conservation. By optimizing module design and manufacturing processes, the energy consumption and emissions of the Single Screw Barrel?system can be reduced to achieve green production.

3. Customized production

With the continuous changes in market demand, customized production has become an important trend in the field of industrial manufacturing. Modular design will make the Single Screw Barrel system more flexible and customizable, and can meet the personalized needs of different customers. By adding or replacing specific modules, the Single Screw Barrel system can be quickly customized and upgraded.

?4. Global collaboration

In the context of globalization, modular design will promote global collaboration in the field of Single Screw Barrel?systems. Through standardized interfaces and protocols, manufacturers in different countries and regions can design and manufacture modules more conveniently, and achieve resource sharing and complementary advantages on a global scale.

In short, modular design has brought huge economic and social benefits to the field of industrial manufacturing by simplifying maintenance procedures, reducing downtime, reducing maintenance costs, enhancing system flexibility and scalability, and improving system reliability and performance. With the continuous advancement of technology and the continuous changes in market demand, the application of modular design in the Single Screw Barrel?system will usher in a broader development prospect.

English

English 中文簡體

中文簡體

浙公網(wǎng)安備33090202000520號

浙公網(wǎng)安備33090202000520號